Innovation is a critical driver of sustainable business growth for the company. It has supported the company in becoming a prominent leader among consumer goods manufacturers and distributors in Thailand and the South East Asian region.

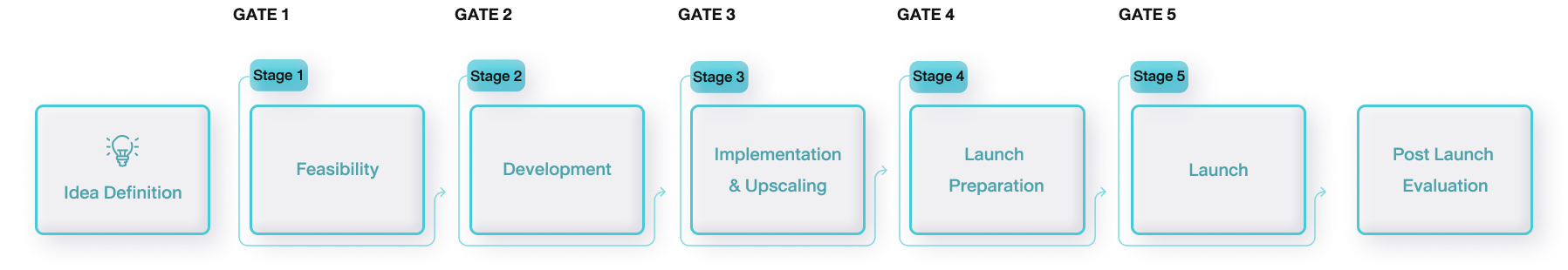

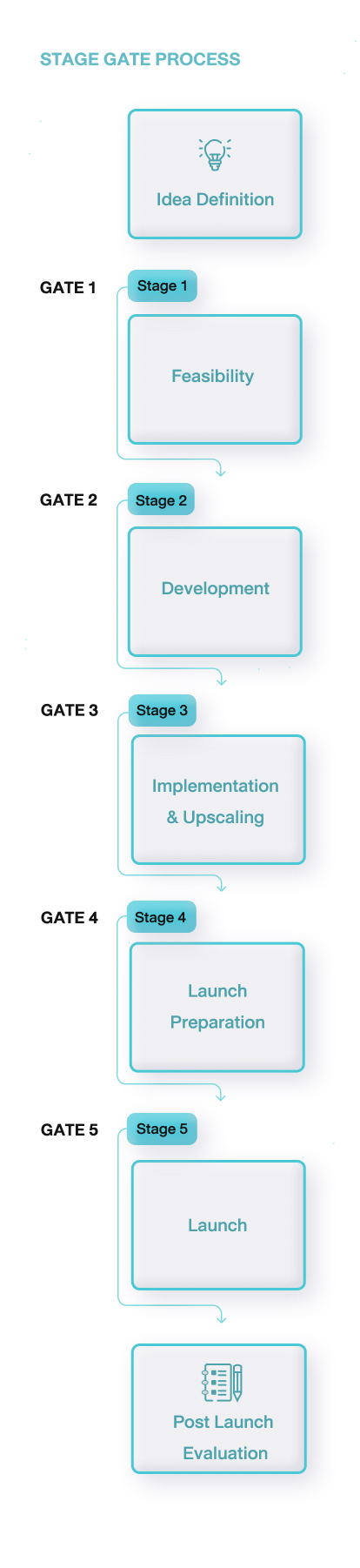

Osotspa prioritizes new product development that drives businessgrowth through the creation of ingredient formulation, packaging, processing, and new product application. The Company has implemented the Innovation management system to facilitate effective decision-making in innovative projects.

The CORE TEAM, each bringing a specific area of expertise, cooperates to move the project forward. They update the GATEKEEPERS with the latest business-critical information to facilitate Go / Hold / No-Go governance decisions at the Gates. Osotspa is committed to providing products that go beyond the basic needs of its consumers. We hope to inspire consumers to have healthy and sustainable lifestyles through the delivery of diverse products. We thus develop new formulations and employ cutting-edge manufacturing technologies to keep our brands ahead of the competition. We also draw on our industry experience and know-how accumulated over the past two centuries

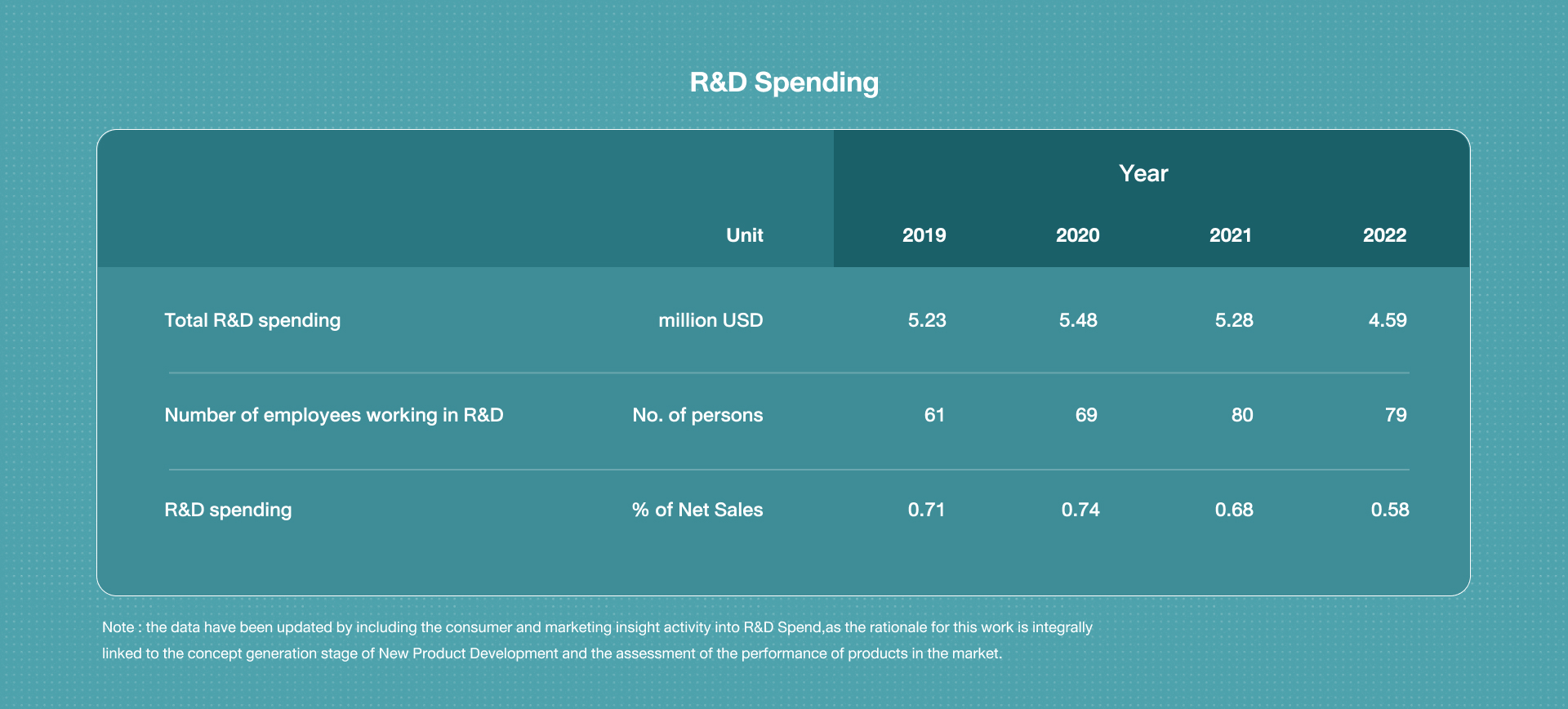

We have refined our innovation infrastructure to ensure that our R&D investments are aligned with our business direction and overall growth. Osotspa’s main innovation and incubation facilities are the R&D Lab at the Huamak headquarters and the Innovation Center at the Thailand Science Park.Laboratory-scale facilities allow us to envision the journey of new products, from the development process in the lab to delivery to the store shelf. This avoids distrupting the main production process and helps save significant costs.

New 8 products

New 8 products Improvement

Improvement

Through collaboration with internal departments and business partners, the innovation process can substantially reduce cost of production. The innovation team serves as the focal point in monitoring the results and outcomes of the initiatives.