Targets

By

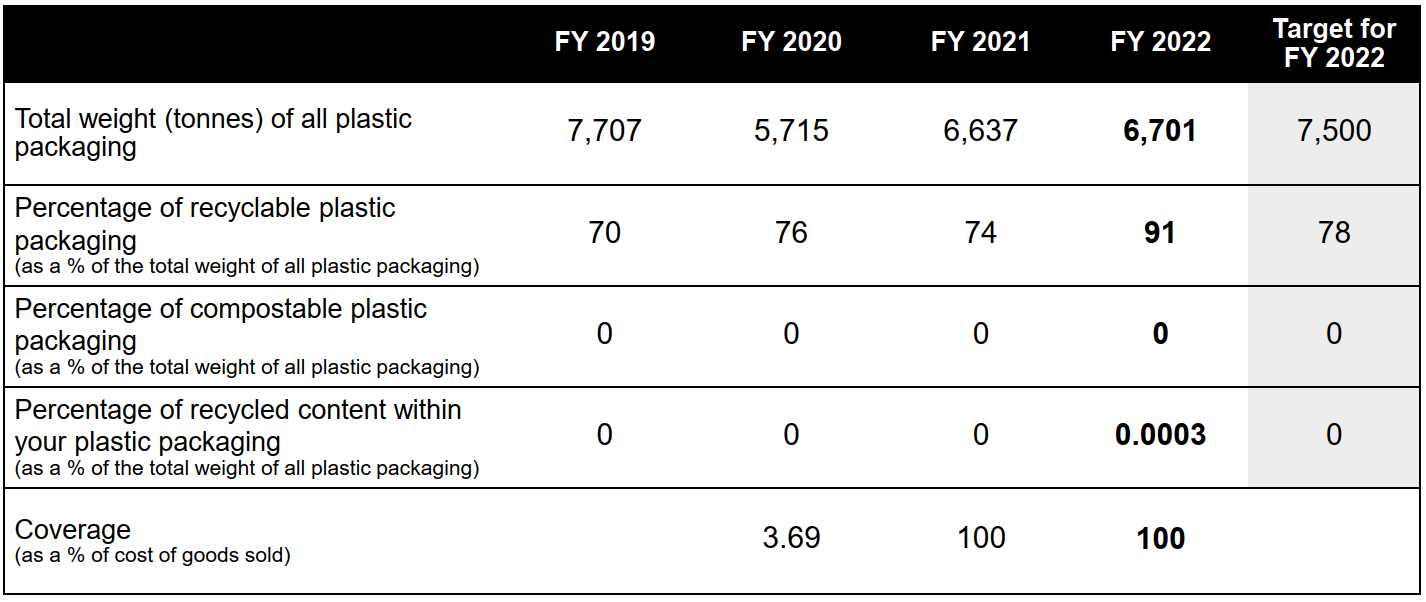

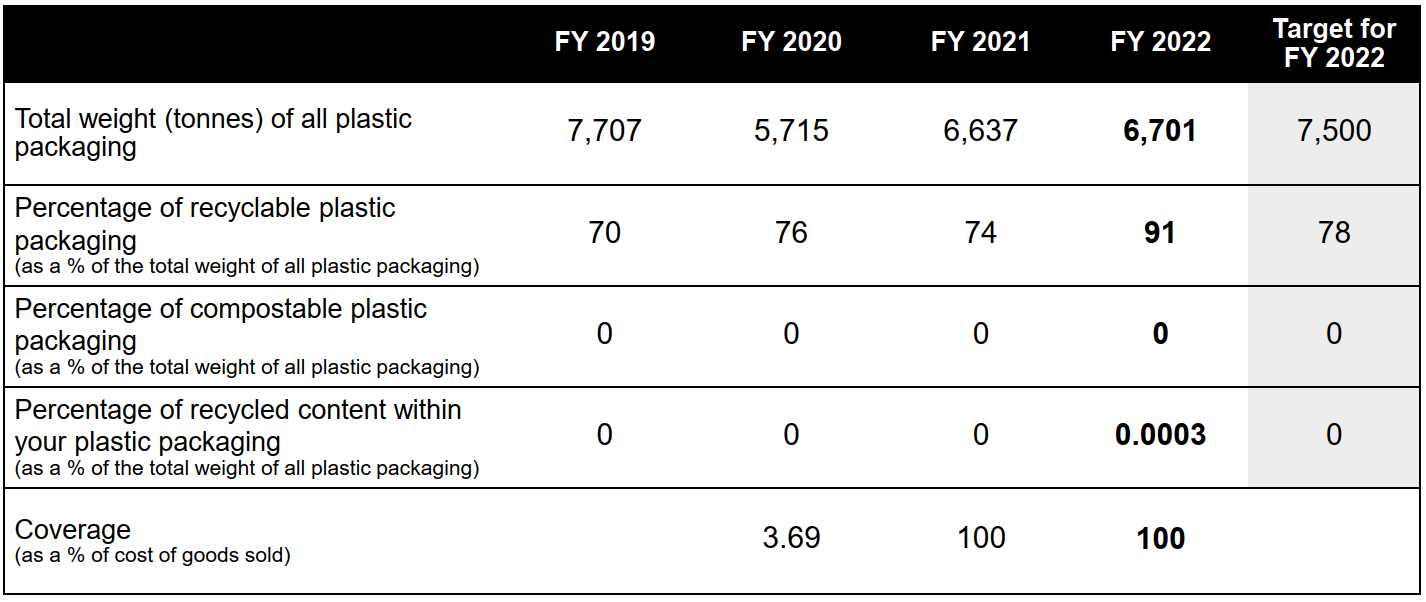

Design packaging with fewer materials used.

Change to recyclable

responsibly sourced materials.

Manage and consolidate product units

Improve shrink-wrapping film and transportation efficiency.

Osotspa has improved its glass bottle packaging production, shifting from the Blow & Blow process (B&B) to the Narrow Neck Press and Blow process (NNPB) in order to reduce packaging materials while maintaining quality.

This has been implemented in the Energy drinks and Functional drinks product packaging processes.

In 2022, the Company replicated this process improvement for four additional product categories: M-150, C-vitt, Slimma, and M-electrolyte.

As a large manufacturer delivering products to be consumed across Thailand

and in many other countries around the world.

Osotspa does not shy from being accountable in terms of post-consumer waste management.

This can be seen in our advanced recycling center in Saraburi province which contributes to the

reduction and recycling of waste by way of resource optimization.

With an end goal to promote sustainable consumption and production,

we at Osotspa never stop seeking ways to enhance the efficiency of our recycling

center and increase the amount of local cullet used in our glass bottle production.

The world s ever-increasing population has unavoidably influenced the consumption and use of natural resources.

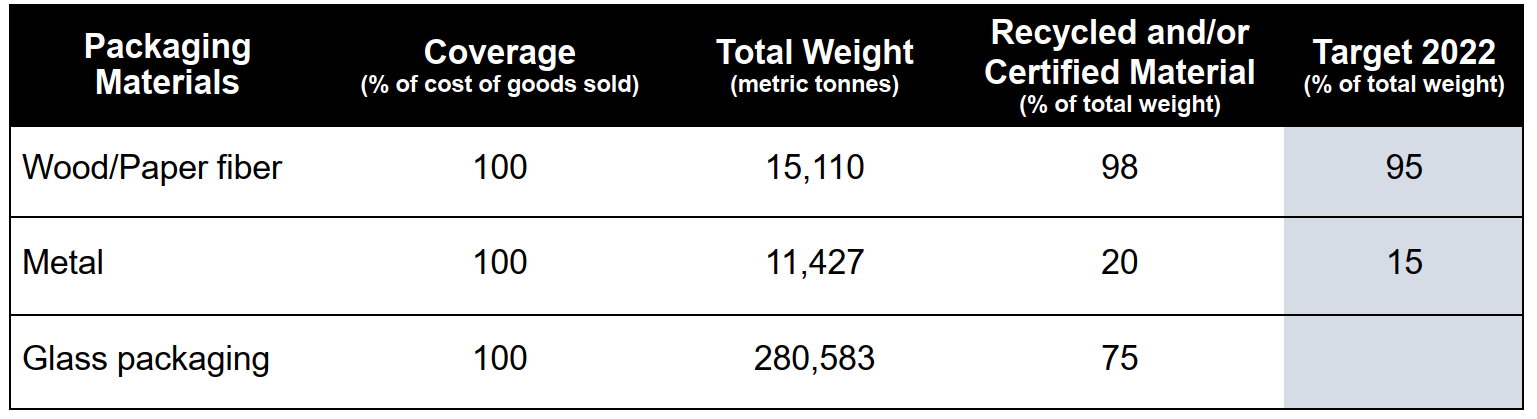

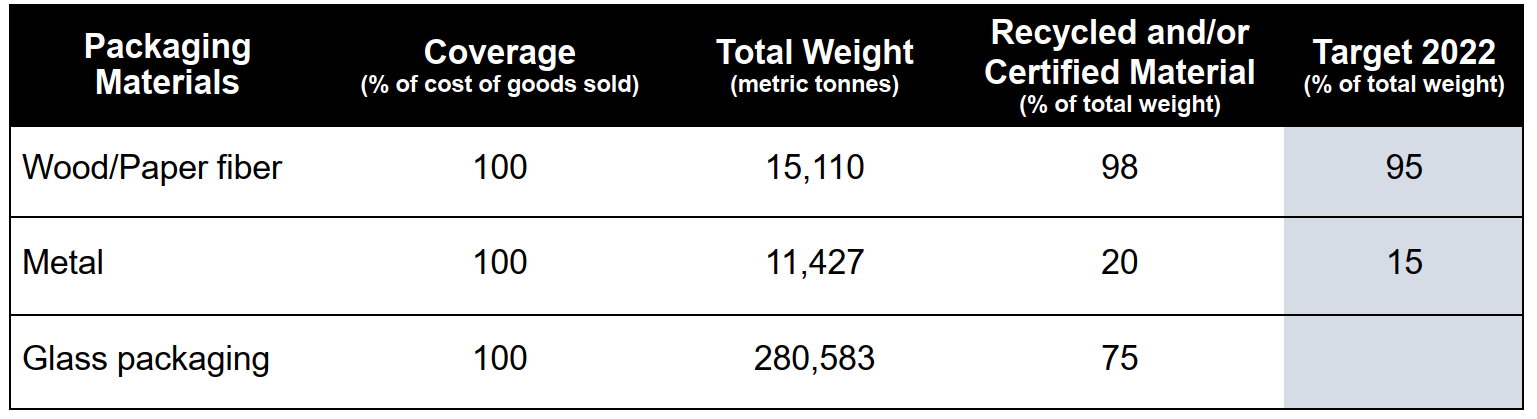

Responsible resource sourcing is one approach to addressing this issue and supporting in the mitigation of degradation while increasing the chances of nature s recovery.

Osotspa understands the value of responsible forestry in the preservation of natural wood resources.

The company thinks about utilizing wood from sustainable sources and uses Forest Stewardship Council (FSC) certified paper material in its packaging production. This will help to reduce illegal deforestation and resource waste, as well as preserve the world s resources for future generations.

The FCS standard is internationally recognized due to its intensive and transparent certification process. Companies that are certified to this standard must be audited throughout the supply chain, from purchasing from suppliers to delivering products to consumers. This is to ensure that the materials used in the products are sourced from responsibly managed commercial forests and that every step of the supply chain is monitored in accordance with the policy and FSC standards.

Osotspa believes that by joining forces with those around us, we can enhance lives and

protect our planet. With this in mind, we are actively working with a wide range of

strategic

partners in the consumer industries, including government agencies, business

associations, academic institutions, suppliers, and peer firms.These partnerships drive

positive change throughout our value chain and help us leverage scale in order to reach

our sustainability goals.