Innovation

Management Approach

Through collaboration with both internal departments and business partners, the innovation process can substantially reduce cost of production and improve OSOTSPA’s sustainability footprint. The innovation team serves as the focal point in monitoring the results and outcomes of the initiatives.

Highlight Performance

An important catalyst for company growth is new product development (NPD). This is underpinned by excellent formulation, packaging, and R&D processing skills, alongside excellent end-to-end implementation of new products, from procurement to consumer delivery.

O-IPM is our internal OSOTSPA process management which ensures efficient delivery and decision-making in our innovation efforts. Integral to this is consideration of

Consumer Relevance

Risk Assessment and Management

Investment

Management of Other Complexities

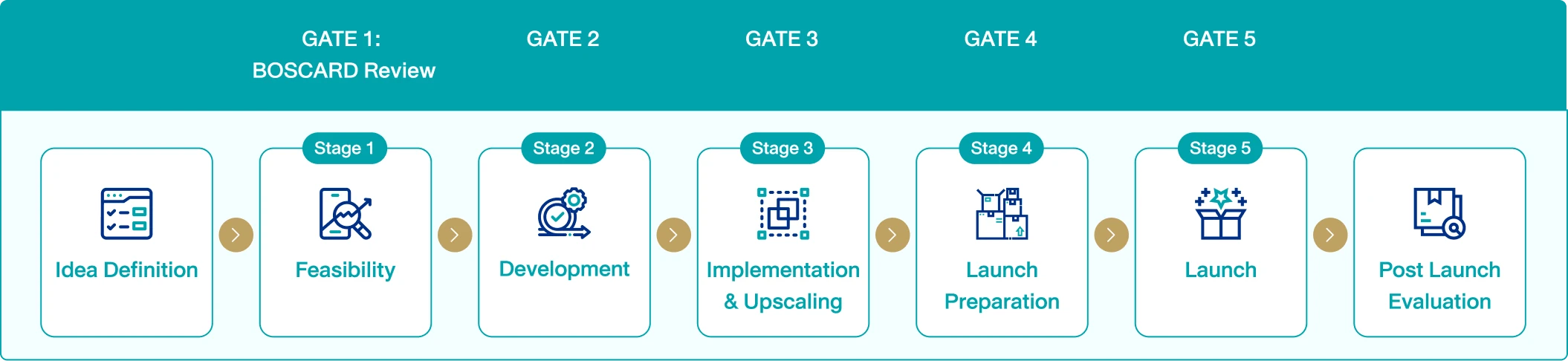

The Stage Gate process (to transform ideas into product launches) has been used by OSOTSPA since 2020.

The Stage Gate Process is OSOTSPA's internal stepwise process to transform generated ideas into commercial launches. There are up to five basic steps after discovery or ideation is completed. These include

These are later followed by a post-launch review. The process can be simplified for less complex projects, ensuring optimal speed with disciplined delivery of each project.

Stage Gate Process

At each gate, there are GATEKEEPERS, who form a cross-functional decision-making board for all projects executed under O-IPM. They make a Go / Hold / No-Go decision based on the project status and plans (e.g. Market Situation, Research, Finance, etc.). Each project has a working CORE TEAM comprising a Project Leader and team members from all functions relevant to that project, such as Research and Development (R&D), Manufacturing, Quality, Supply Chain, Marketing, Trade & Sales, and Finance. The CORE TEAM, each bringing a specific area of expertise, cooperates to move the project forward. The CORE TEAM, who comprise all functions needed to deliver a project, will work along the whole journey of an NPD. Each team member’s deliverables focus on their area of expertise and will vary depending on the phase of the project and the relevant GATE.

The team updates the GATEKEEPERS with the latest business-critical information to facilitate Go / Hold / No-Go governance decisions at the Gates.

OSOTSPA is committed to providing products that go beyond the basic needs of its consumers. We hope to inspire consumers to have healthy and sustainable lifestyles through the delivery of diverse products. We thus develop new formulations and employ cutting-edge manufacturing technologies to keep our brands ahead of the competition. We also draw on our industry experience and know-how accumulated over the past two centuries.

We have refined our innovation infrastructure to ensure that our R&D investments are aligned with our business direction and overall growth. OSOTSPA’s main innovation and incubation facilities are the R&D Lab at the Huamak headquarters and the Innovation Center at the Thailand Science Park. Laboratory-scale facilities allow us to envision the journey of new products, from the development process in the lab to delivery to the store shelf. This avoids disrupting the main production process and helps save significant costs.

OSOTSPA aims to continuously improve our internal O-IPM process. In 2023 - to increase agility, market competitiveness, complexity reduction and resource optimization - the process was rolled out for the International Business with the S.E. Asian country teams involved. In addition to evaluating post launch performance in the market, teams also track what was done well during the process and what could have been done better.

We introduced digital tools in 2023 to store all significant information (e.g. trial and test results, artwork, timelines, product design, packaging drawings). Information security is a top priority with multiple safeguards to ensure data is both accessible to authorized staff only and confidentiality is secure for the future.

In 2023, Osotspa accelerated our product innovation in new formats and/or new benefits across beverages portfolio in anticipation of evolving consumer trend and lifestyle and acquiring new and growing consumer segments, such as white collar, new economy workers, silver generation, and millennials. OSP launched M-150 sparkling energy drinks with modern design in can format, targeting younger and premium consumer segments, aligned with our premiumization strategy. Our functional drinks portfolio offers Peptein Drink D with new-easy-to-drink taste, high vitamin D to boost immunity, and enhancing brain function with original soy peptide. Calpis also introduced new benefits and seasonal flavor creation, including Calpis Lacto Original Fiber 5,000 mg. for balancing the digestive system and Calpis Lacto Soda Aomori Apple flavor, which come with refreshment and benefits from lactobacillus. C-Vitt offers 0% sugar for healthier choice comprising of lemon, orange, and newly launched peach flavors. In addition, Osotspa introduced healthier beverages under Shark brand, including Shark Soda Lemon Mocktail and Shark Soda Ume flavor with sugar free and zero calories.

For personal care portfolio, Babi Mild transformed its entire portfolio into new 100% organic formulation and eco-friendly packaging to create safe and sustainable products and reduce plastic usage. Roll-on deodorant under Twelve Plus and Exit brand continued to innovate while leveraging its strength in high quality fragrance and differentiating proposition on nourishing the skin and longer-lasting protection.

Shelf-life testing efficiency improvement

A collaborative project with Amatek, a global manufacturer of electronic instruments and electro-mechanical devices, shortened product shelf-life testing from 12 months to 1 month by using appropriate storage conditions in a Sun Test machine. This helps us quickly analyze product properties, supporting both troubleshooting and product stability studies. The Sun Test machine, operated under suitable conditions, can simulate the scenarios of a product stored at a warehouse, a product in transport, and a product stored on shelf. This ability secures quality during product development and enables a quicker response to consumer complaints.

Reduce testing time and increase responsiveness to consumer complaints

Optimization of bottle rinser operation

Taking a holistic view of beverage thermal processing, we have studied the optimization of bottle rinser operations. Time and temperature were optimized in the pilot plant to confirm rinser function was within specifications, while water and energy use was cut through modified operating conditions. Optimum rinser conditions delivered high double-digit % reductions in both water and energy.

Savings exceeding

Energy reduction of

GHG emission reduction of

Optimization of raw material format delivered to international business manufacturing

Previously, raw material kits in the liquid format were produced in Thailand and exported to Myanmar. Aiming for sustainability, the R&D team re-developed the kits into a powder form with development of a new, innovative, stepwise mixing process. The savings and sustainability benefits from this project can be seen at several points along the materials supply chain - starting at raw materials preparation, then at transportation, and finally at the Finished Goods production operations.

Savings exceeding

Water reduction of

Energy reduction of

GHG emission reduction of

Post-Consumer Recycled (PCR) Resin

OSOTSPA has signed an MOU with Union J Plus in Thailand for a packaging innovation project within the circular economy framework (Make-Use-Return).

This project involves utilizing plastic waste from our manufacturing line by collecting the waste plastic for recycling processes and reprocessing it into new materials. The whole process up to Post-Consumer Recycled (PCR) resin production is managed by Union J Plus. These PCR resins are then converted to shrink PE bundle film for use in beverage manufacturing by the Sawasdee plant.

Currently, 30% PCR resins are used in OSOTSPA manufacturing plants, achieving a waste reduction equivalent to 169.9 tons of virgin resin per annum.

Reducing thickness in aluminum cans with Aluminum Loop CAN

As part of the “Aluminum Loop CAN” scheme, OSOTSPA has cooperated with Thai Beverage Can since April 2023 to reduce aluminum consumption by using cans with reduced wall thickness in new products.

The reduction of aluminum consumption totals

Aiming for complete recycling, 100% of aluminum cans produced by OSOTSPA will be part of the “Aluminum Loop CAN” scheme. The collection process and quantity of Aluminum Loop CAN packs in the scheme are transparent and traceable. Thailand is the only country in Southeast Asia ready for the complete management of aluminum can waste.

Technical abilities that deliver speed and efficiency are vital to our production process. Hence, in 2023 we partnered with U.S. firm specright to transform our packaging specification management system into an automated specification platform. This represented a leap forward in our digital transformation, enhancing workflow efficiency, accuracy, and the speed of our technical process across all OSOTSPA categories. The platform serves as a scalable enabler to streamline the capture and handling of specification data. It also strengthens our internal specification processes for new product development, cost-savings, and sustainable development initiatives.

working in R&D positions

Total R&D spending of

Talcum Harmonized Packaging

Osotspa has conducted research and development with a focus on sustainable design by reducing the amount of plastic used in the packaging of Baby Talcum and Cool Talcum products under the Babi Mild, Twelve Plus, and Exit brands. This encompasses both existing and new products. The company has focused on reducing the weight of both bottles and caps, as well as streamlining the variety of bottle sizes to three standard options and using a single cap size for all bottles. These efforts have resulted in a 119.59 ton annual reduction in plastic waste which equal to annual 802.10 tCO2e avoided emissions.

Concurrently, these initiatives have led to a reduction in the weight of shrink film used for bundling Baby Talcum products. The company has replaced PVC shrink film with POF, which is 45% thinner. This change has resulted in an additional 4.03 tons of annual plastic waste reduction.

Osotspa aims to implement this packaging system for new products in the Baby Talcum and Cool Talcum categories in the future, that will further reduce plastic usage and product weight.

from 2021

Reduce Greenhouse Gas Emission

In order to stay on top of changing consumer expectations, Osotspa continues to invest in and leverage our research and development (R&D) for products and packaging innovations, including alternative materials, moving towards overall efficiency improvement and sustainability. Our long-term target R&D spending is at least 1% of revenues and actual spending was 0.3% of net sales. We have bolstered our innovation infrastructure for growth, fully equipped with more than 65 researchers and advanced equipment. Our R&D team works with manufacturing, sales and marketing, and other cross-functional teams, as well as with our business partners and international regulatory affairs to achieve the best possible outcomes for consumers, optimize R&D processes, and exchange insights on market trends, technology, and best practices. Quality comes first and hence Osotspa has secured ISO 9001 accreditation for our label facilities at Huamak. Indeed, we remain committed to evolving our technical acumen via both training and the strengthening of our facilities and equipment at all sites. Our main innovation and incubation facilities are the R&D Lab at the Huamak headquarters and the Innovation

Center at the Thailand Science Park. Having in-house laboratory-scale facilities enhances our product and packaging development capabilities without interrupting the main production process. Osotspa collaborates with a number of researchers from the National Science and Technology Development Agency (NSTDA) and has joined hands with leading universities in Thailand, including King Mongkut’s Institute of Technology Ladkrabang (KMITL), King Mongkut’s University of Technology Thonburi (KMUTT), Mahidol University, and Walailak University, for in-depth study and access to abundant analytical services and information networks. These collaborations have led to a number of breakthrough innovations and initiatives.