Human Rights

Human Rights at Osotspa

incidents of human rights violations are

2023

2024

Note: The Osotspa Group’s factories and operational areas, totaling 16 locations, are where the Company conducts its business activities across the supply chain, including activities with business partners.

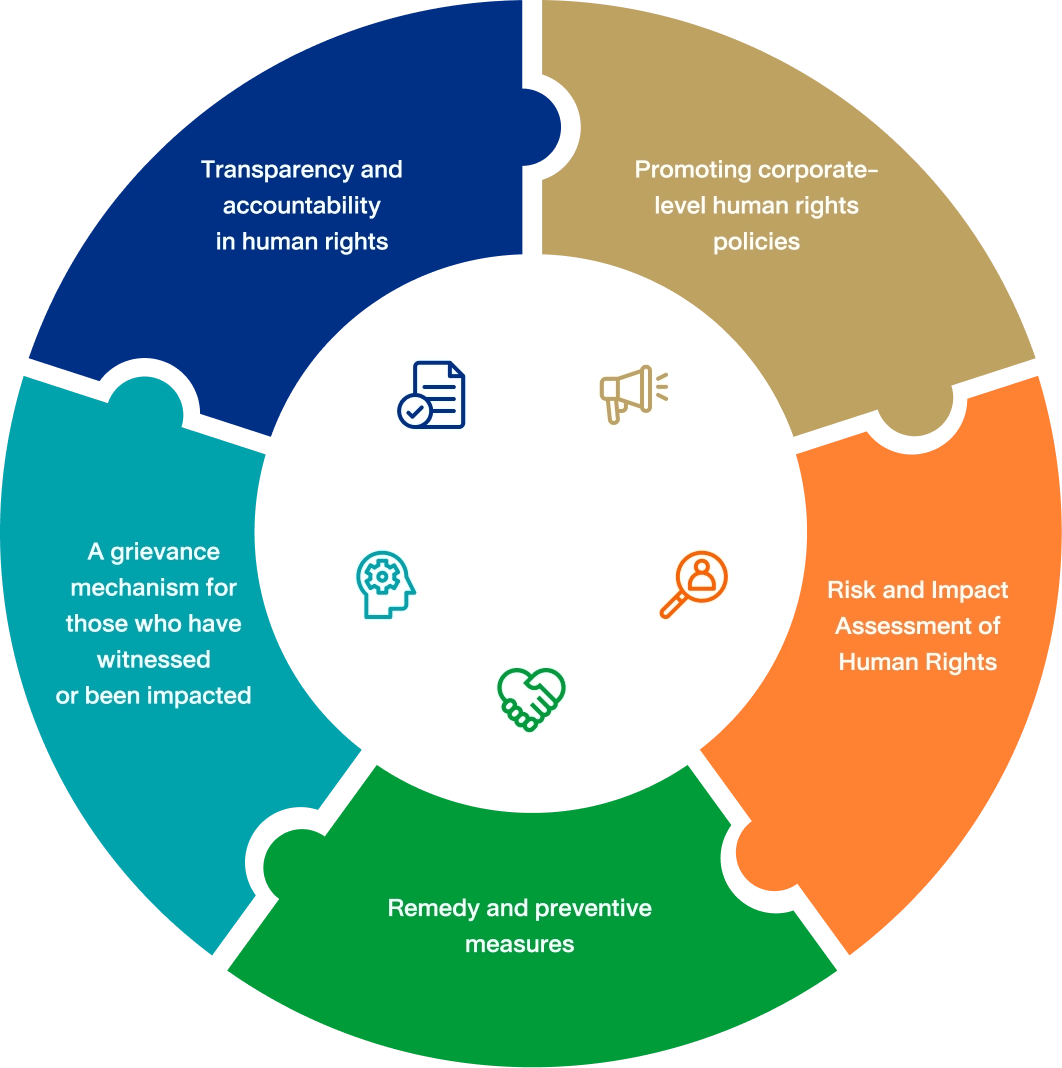

Management Approach

Human rights risk management is one of the pillars of the Company's economic, social, and environmental (ESG) strategy, which aims to improve efficiency and ensure business continuity across the supply chain. Through the strategy, the company demonstrates its commitment to enhancing the quality of life for all its stakeholders. Our stakeholders include employees, partners, contractors, business partners, joint ventures, as well as other business relationships including new mergers and acquisitions, customers, consumers, and related communities. Additionally, we consider at-risk or vulnerable groups such as pregnant women, LGBTQI+ groups, the elderly, disabled people, migrant workers, third-party employees, indigenous peoples, and local communities. In short, all individuals who may be affected by the company's business operations and other activities related to business activities throughout the value chain.

We investigate and identify human rights risks to ensure proper management and mitigation. Human rights principles are also upheld when treating our stakeholders. These efforts help the Company maintain a positive organizational image and fosters a healthy workplace environment, resulting in greater employee satisfaction. This, in turn, enhances work efficiency and ensures sustainability in business operations.

Human Rights Due Diligence: HRDD

Osotspa has conducted comprehensive Human Rights Due Diligence (HRDD), in accordance with the UN Guiding Principles on Business and Human Rights (UNGPs).

In addition, the Company has instituted a Human Rights Policy that aligns with both Thailand's human rights policy and International Human Rights Standards. The principles of this policy reflect

- Labor Protection Act B.E. 2541 (1998)

- Universal Declaration of Human Rights : UDHR

- International Covenant on Civil and Political Rights : ICCPR

- International Covenant on Economic, Social and Cultural Rights : ICESCR

- United Nations Global Compact: UNGC

- UN Guiding Principles on Business and Human Rights: UNGP

- Declaration of the International Labor Organization (ILO) on Fundamental Principles and Rights at Work, and

- the related components in the Voluntary Principles on Security and Human Rights

These serve as guidelines for managing human rights risks.

In the Human Rights Due Diligence (HRDD) process, key issues to be assessed include

- Forced labor

- Human trafficking

- Child labor

- Freedom of association

- Right to collective bargaining

- Discrimination

- Health & Safety

- Equal remuneration

Human Rights Due Diligence (HRDD): The Procedure

Performance Highlights

Human Right Risk Assessment: HRRA

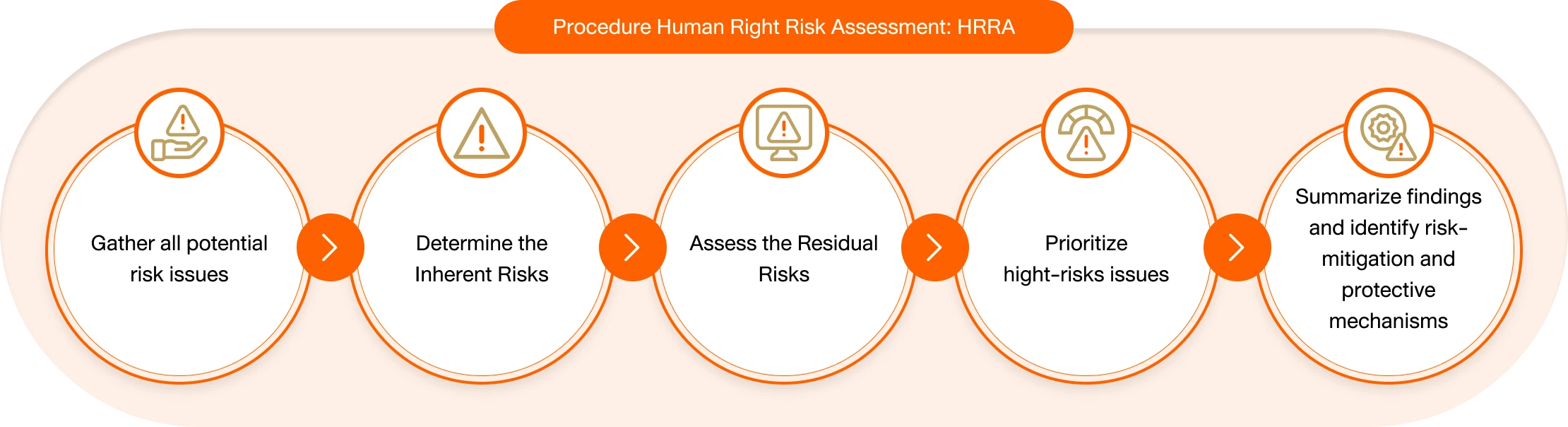

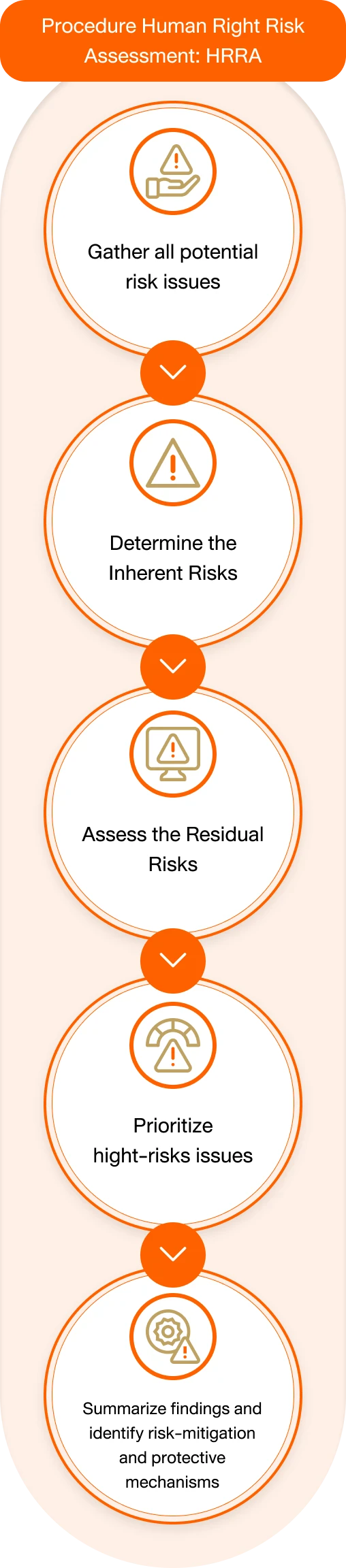

Osotspa conducted a Human Rights Risk Assessment (HRRA) in which it specified the scope for the assessment and then identified related human rights issues across all factories and operational areas within Osotspa Group, including those of its business partners. The assessment is carried out every three years with the aim of identifying, preventing, and mitigating potential human rights violations. The findings lead to a determination of remedies within the organization. In addition, business activities throughout the supply chain are examined to ensure that there are no violations of human rights and that any potential risks can be managed promptly.

Assess human rights risks throughout the supply chain

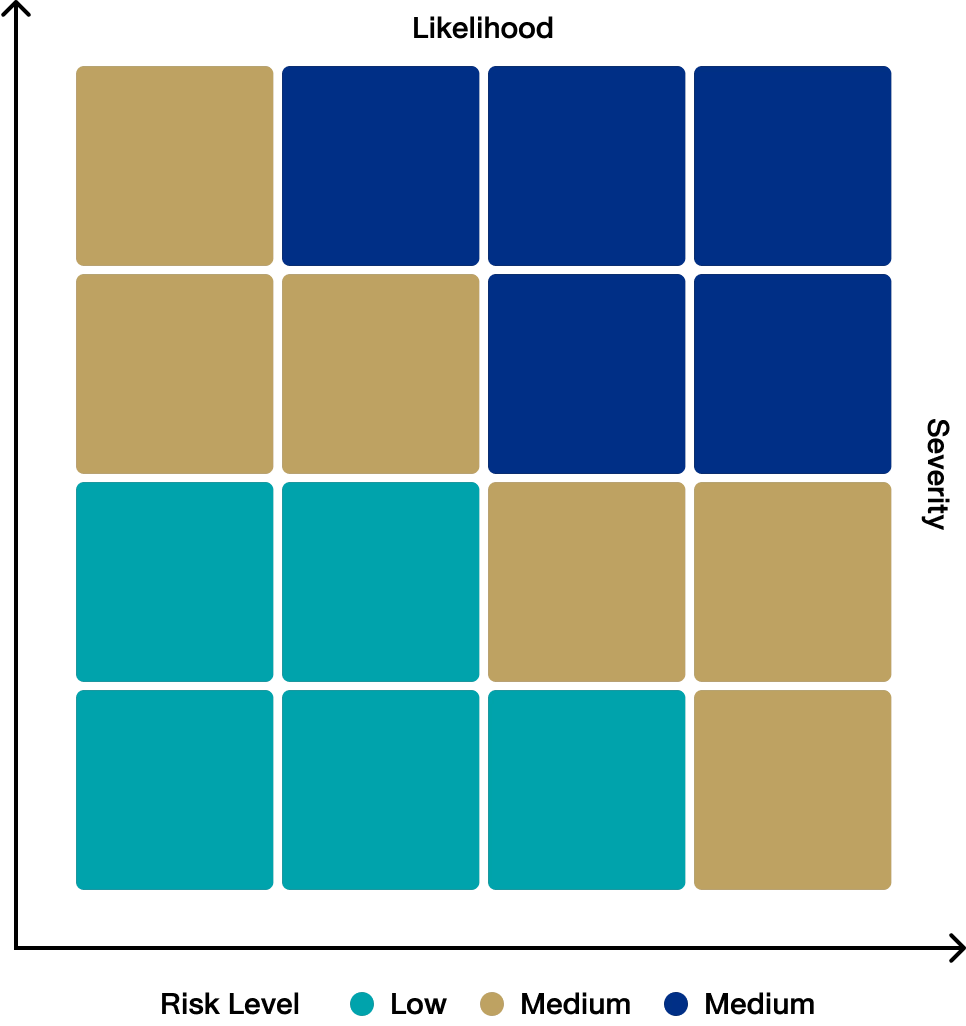

Severity of Impact and Likelihood of Occurrence

Osotspa conducted a comprehensive human rights risk assessment, using a risk assessment matrix to identify and prioritize each potential issue. This assessment evaluated both the severity of the impact and the likelihood of occurrence of each risk, while also considering factors such as the organization's size, scope, and mitigation capabilities.

Implementing these guidelines helps the Company prioritize and manage human rights risk issues based on their severity. Issues with a high level of severity and likelihood of occurrence are classified as high risk. The Company moves with alacrity to manage and prevent the occurrence of these issues in order to reduce their severity, as well as the likelihood that they may occur, and continuously monitors the progress of operations.

Risk Issues in the Organization

Risk Issues in the Value Chain

Results of the Human Rights Assessment (HRRA)

In 2023, Osotspa completed a comprehensive Human Rights Risk Assessment, covering 100% of its operational sites (13 locations). The assessment identified five key internal human rights risk areas. For all identified risks, appropriate mitigation measures and preventive mechanisms have been implemented accordingly

In 2024, Osotspa continues to review and monitor these key risk areas to ensure the effectiveness of its mitigation efforts. The company remains committed to this ongoing process and plans to conduct a new full-scale Human Rights Risk Assessment in 2026.

Risk

Potentially affected factories and operational areas

Potentially Affected Rights Holder

Risk Mitigation Measures and Preventive Mechanisms

Risk

Potentially affected factories and operational areas

Potentially Affected Rights Holder

Risk Mitigation Measures and Preventive Mechanisms

Risk

Potentially affected factories and operational areas

Potentially Affected Rights Holder

Risk Mitigation Measures and Preventive Mechanisms

Risk

Potentially affected factories and operational areas

Beverage Production

Potentially Affected Rights Holder

Risk Mitigation Measures and Preventive Mechanisms

Risk

Potentially affected factories and operational areas

Potentially Affected Rights Holder

Risk Mitigation Measures and Preventive Mechanisms

Approaches and Procedures for Monitoring and Reporting on Human Rights Risks

Osotspa has established whistleblowing and reporting channels to empower stakeholders and rights holders throughout the entire value chain to report incidents of human rights violations or non-compliance with human rights policies. Whistleblowers will receive protection throughout the investigation process. Information received through these channels is of paramount importance for monitoring and assessing the company's performance in relation to human rights.

The Company will use the information gathered through these channels to improve and refine existing risk mitigation and prevention mechanisms, as well as to develop additional measures to address human rights issues that may arise as a result of both direct and indirect business operations. The Company is committed to making consistent improvements to the efficacy of the comprehensive human rights inspection process.

To uphold transparency, the Company disseminates information about its human rights endeavors through the Osotspa website, which is accessible to the public.

Right holders involved in all affected value chains can report and provide confidential information through the following channels:

Report

Hotline

Call Center

Letter

Contact Head of Internal Audit

at Osotspa Public Company Limited, 132 Klongchan Post Office, Klongchan, Bangkapi, Bangkok 10240Letter to Chairperson of Audit Committee or Directors

at Osotspa Public Company Limited, Building 5, No. 348, Ramkhamhaeng Road, Hua Mak Subdistrict, Bang Kapi District, Bangkok, 10240

Remedial Mechanisms for Human Rights Violations

Osotspa is committed to upholding the highest standards of ethical conduct in business and recognizes the critical role of human rights. In support of this, the organization assesses potential human rights risks and has implemented additional measures to prevent and mitigate such risks. Furthermore, the Company is fully committed to monitoring and reporting on its performance to ensure the most effective management of human rights.

Osotspa consistently evaluates its policy commitments and responds promptly to address any complaints or violations that may arise, prioritizing effective remedial actions for those affected. In cases of human rights violations, the Company takes immediate corrective measures, focusing on rehabilitation and compensation for affected rights holders, while also addressing any damages resulting from its business activities. These remedial actions may involve various forms of compensation (such as apologies, financial or non-financial remedies), penalties, and proactive measures to prevent future incidents.