Waste Management

Highlight Performance

Maintain Zero Waste to Landfill

Management Approach

Osotspa is committed to minimizing environmental impact through a holistic and sustainable waste management approach, grounded in the 3Rs principle: Reduce, Reuse, and Recycle. This aligns with the United Nations Sustainable Development Goal 12: Responsible Consumption and Production. Our strategy incorporates waste audits to identify opportunities for improving waste performance, allowing us to better manage resources and reduce waste generation at its source. We implement action plans to reduce waste generation, along with quantified targets to minimize waste across our operations. The company continually drives progress through investment in innovation and R&D to minimize waste, while also providing waste reduction training to employees to foster a culture of sustainability throughout the organization. Our waste management system includes the integration of recycling programs to reduce the waste sent to landfill, helping to promote circular economy practices. Importantly, our efforts in waste diversion from landfill are certified by 3rd party verification, ensuring transparency and compliance with internationally recognized standards such as GRI 306-3, 306-4, 306-5, and 13.8. These efforts reaffirm Osotspa’s strong commitment to sustainable growth and environmental stewardship.

Reduce

Reuse

Recycle

Zero Waste to Landfill

In line with our goal of zero waste to landfill, the Company minimizes manufacturing waste from our domestic and overseas operations with a pragmatic approach, one that complies with local regulatory requirements and supports the circular economy.

Food Loss & Food Waste

Osotspa utilizes a food loss and waste management strategy as an operational guide, aiming to reduce waste and address climate change issues.

The Company examines raw material losses and food waste at each stage of the value chain, spanning beverage production to storage, transportation, distribution, and ultimately arrival at the end-consumer.

Food Loss & Waste Impact

| Food Loss & Waste Impact (Tons) | FY 2020 | FY 2021 | FY 2022 | FY 2023 | FY 2024 |

|---|---|---|---|---|---|

| Total food loss and food waste (tons) | 13,324.52 | 12,453.49 | 12,469.31 | 12,210.99 | 12,341.40 |

| Food waste disposed and repurposed (tons) | 11,534.06 | 9,335.22 | 10,506.85 | 9,418.37 | 8,463.95 |

| Food waste disposed (tons) | 1,790.46 | 3,118.28 | 2,962.46 | 2,792.63 | 3,877.45 |

| Total food loss and food waste intensity per unit of beverage sales (tons per million Baht) | 0.083 | 0.137 | 0.135 | 0.132 | 100 |

| Data coverage (%) | 100 | 100 | 100 | 100 | 100 |

Break-Down of Food loss & Waste Volumes by Lifecycle Stage

Manufacturing

Storage

Transportation

Customer

Operational Guidelines

Osotspa recognizes the significance of Sustainable Food Waste Management and has established guidelines for effective implementation while targeting Zero Waste to Landfills by 2030. In line with the United Nations’ Sustainable Development Goals (SDGs), particularly SDG12, which emphasizes ensuring sustainable consumption and production patterns, and SDG target 12.3, Osotspa aims to halve per capita global food waste at the retail and consumer level while reducing food losses along production and supply chains. To attain these objectives, the Company is adhering to the following comprehensive guidelines.

Performance Highlights

Programs established to measure food loss & waste

Food Loss Tracking and Recording System for the Manufacturing Process

The company has implemented a program to reduce product loss during the production process, aiming to enhance collaboration across all functions throughout the manufacturing value chain. This initiative seeks to continuously and effectively minimize production-related losses. A workshop was organized to encourage idea generation and propose projects focused on reducing food loss within the production process. As a result, 36 actionable projects were identified, each with the potential to significantly reduce food loss during manufacturing.

In 2023, the Company’s manufacturing factories set a goal to control waste in the production process by reducing 2% of the total loss in 2022, equivalent to 180,118 kilograms. The actual reduction amounted to 874,143 kilograms, representing a substantial decrease of 9.71

In 2024, a number of projects to reduce product losses in the manufacturing process have been initiated, aiming to enhance cooperation among all production units throughout the manufacturing value chain to decrease production losses consistently and effectively. After a brainstorming session and project presentations focused on reducing food loss during the manufacturing process, 36 projects were given the green light. These projects are expected to result in a 3% reduction in production losses compared to the previous year, representing 243,952 kilograms.

Minimizing Food Waste in the Production Processes

"Initiative to Reduce Product Loss at the start of the process"

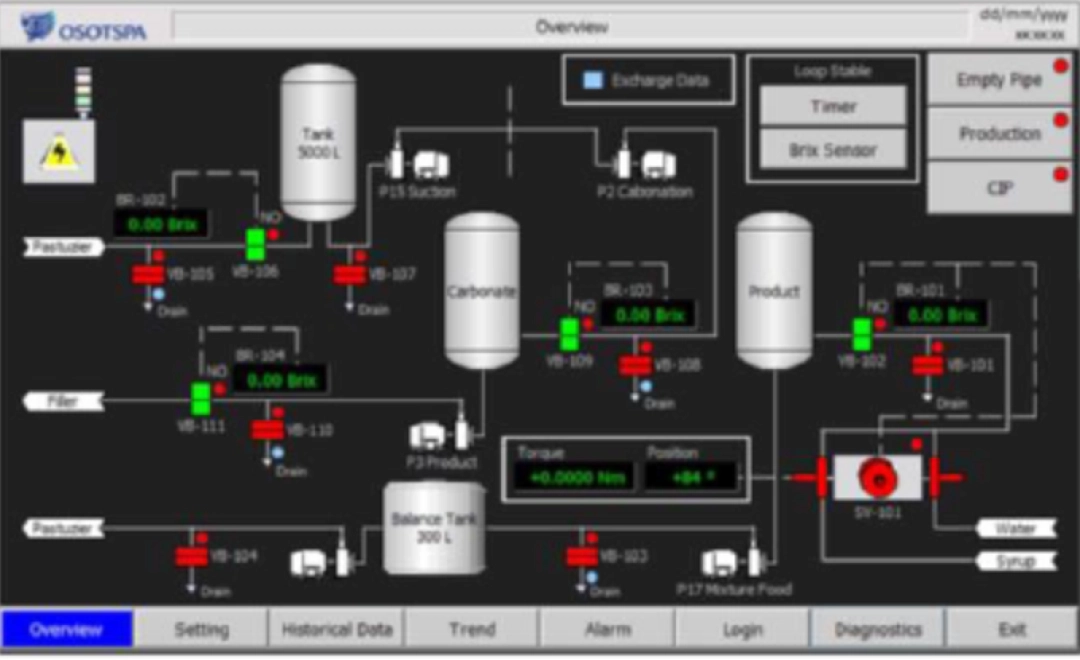

Osotspa has invested over 1.5 million baht in manufacturing operations, integrating automatic product quality measurement technology and an automated control system to replace manual labor. This has resulted in reduced product loss and decreased time spent on quality inspection processes at the start of production.

Leading to a decrease in product loss of

"Project to Reduce Product Loss Remaining in Machines Prior to Washing by Extending the Production Period"

The beverage factory conducted studies, experiments, and analyses on the production process to determine the most effective production time. This allows for the production of high-quality products while minimizing product loss.

As a result of these efforts, product loss has been decreased by

Repurposing Food Scraps for Beneficial Use

In 2023, Siam Cullet Co., Ltd., a subsidiary of Osotspa responsible for waste management within the group, partnered with ATHIBHATTKIJFAIFAH Co., Ltd., the operator of a biogas electricity generating plant.

Together, they repurposed deteriorated beverages as raw material for electricity production. This joint initiative successfully utilized 143,490 kilograms of beverages to generate electricity. Both companies plan to maintain this practice going forward.

Community Food Waste Donation Project

"Organic Fertilizer Project"

Siam Cullet Company, on behalf of Osotspa, donated beverage waste from deteriorated products to Wat Chak Daeng in Samut Prakan to produce ‘Customized Organic Fertilizer’. The organic fertilizer, which is useful for enhancing crop growth, is made from composting food waste collected from temples and communities alongside donated deteriorated beverages. A total of 2,000 kilograms of organic fertilizer were utilized within the temple premises and given to local farmers, contributing to the income of Wat Chak Daeng (the pioneering temple in waste management and environmental conservation).

Additionally, 10,000 kilograms were allocated to Bangkok’s Public Parks Divisions. In total, 12,000 kilograms of waste were donated for community benefit.

Waste Management Training for Employees

Osotspa conducts waste management training for its employees in accordance with ISO 14001:2015 and ISO 45001:2018 standards. The training covers all aspects of waste management, including handling, monitoring, and verification of waste removal from the factory premises. It aims to enhance employees’ knowledge, understanding, and skills in managing waste systematically, safely, and in an environmentally friendly manner, while supporting effective compliance with the company’s environmental and safety policies. Furthermore, Osotspa extends its commitment to workforce development by providing training and reskilling programs that equip employees to mitigate the potential negative impacts of industrial transformation and climate transition, ensuring long-term resilience and sustainable growth.