Energy and Climate Management

Highlight Performance

Energy Consumption

Greenhouse Gas Emission (Scope 1&2)

Energy & Climate Management

In order to reduce the environmental footprint of our business operations, we adopt diverse solutions for energy & climate change management. These include new initiatives and collaborative actions that drive environmental innovation, both within our operations and across the value chain.

In 2023, Osotspa implemented numerous energy saving initiatives with the objectives of minimizing energy use, promoting renewable energy use, and lowering greenhouse gas emissions from our business activities.

Reducing Energy Consumption

Osotspa is conscious of the adverse impact our business may have on the environment. To reduce its environmental footprint, the Company prioritizes efficiency enhancement. Such enhancement is achieved by streamlining our processes and managing energy consumption in our business operations. The Company also believes that energy-efficient operations enable the business to be more competitive via reduction of energy costs.

Renewable Energy Utilization*

*Including the amount of renewable energy used from palm kernel shells, biomass pellets, and self-generated solar power.

Harnessing Renewable Energy

Osotspa promotes the use of renewable energy from a variety of sources such as wind, solar, biogas, and biomass, thus reducing reliance on conventional energy sources which tend to be huge contributors to global warming emissions. To support the mitigation of climate change, we are actively exploring portfolio diversification into renewable energy projects that reduce Green House Gas emissions, in line with the UN SDGs.

Furthermore, effective equipment and machinery have been installed, incorporating cutting-edge technology to maximize energy efficiency

Climate Advocacy and Financial Planning

Osotspa Public Company Limited is committed to supporting national and global efforts to limit global temperature rise to below 1.5°C and achieve net-zero greenhouse gas (GHG) emissions in line with the Paris Agreement.

We actively engage in climate-related public policy and collaborate with both public and private stakeholders, including as a member of the Thailand Carbon Neutral Network (TCNN), to advance a low-carbon economy. We expect our trade associations to align with the Paris Agreement, and we address any misalignment through constructive engagement or appropriate action.

Osotspa integrates climate considerations into strategic investment and financial planning. We are phasing out high-emission assets, adopting cleaner production technologies, and modernizing facilities to reduce GHG emissions. All new investments are evaluated against our SBTi-aligned roadmap, ensuring alignment with our long-term decarbonization goals. In line with the Paris Agreement, our financial planning also considers CapEx and OpEx implications to balance climate ambition with financial responsibility.

To guide our climate policy engagement, Osotspa has established a structured management approach consisting of the following key activities:

-

Policy Alignment Assessment

Periodically review public policies and the climate-related positions of trade associations to evaluate consistency with the Paris Agreement and our SBTi-aligned targets.

-

Monitoring and Oversight

Continuously track climate policy developments, assess alignment risks related to association memberships, and oversee progress on decarbonization and phase-out activities.

-

Stakeholder Engagement

Actively engage with internal and external stakeholders to foster shared understanding and alignment on climate policy priorities and investment decisions.

-

Transparency and Disclosure

Publicly report Osotspa’s climate policy engagement activities, including positions taken by relevant trade associations, investment transition plans, and any actions taken in response to misalignment.

Through these actions, Osotspa ensures that our direct and indirect influence, financial planning, and investments support a science-based, policy-aligned, and transparent transition toward climate resilience and a net-zero future.

Performance Highlights

Heat Recovery

Recovering Heat Waste From The Glass Bottle Production Facility To Produce Steam For The Beverage Production Facility.

Double Pass Regenerator system

Improving Efficiency Of Preheating By Adopting A Double Pass Regenerator System.

Optimization of Raw Material Format Delivered to International Business Manufacturing

In 2023, Osotspa invested over 500,000 THB to redevelop the kits into a powder form, utilizing a new, innovative, stepwise mixing process. The savings and sustainability benefits from this project are evident at several points along the materials supply chain—starting from raw materials preparation, through transportation, and finally at Finished Goods production operations. This initiative aims to enhance sustainability and reduce greenhouse gas emissions by up to 510 tCO2e per year. Additionally, it reduces energy consumption by over 6,670 GJ per year and water usage by 2,300 m³ per year, resulting in savings exceeding 30 million baht per year.

Eliminate last hot water step Project

Osotspa has researched and developed production process that maintains same efficiency while reducing energy consumption by removed step of hot RO water recirculation in CIP (Cleaning In Place) process, which overlaps with the SIP (Sterilization In Place) process. This change reduces greenhouse gas emissions by over 86 tCO2e/year, energy consumption by over 1,000 GJ/year, and water usage by 480 m³/year. The research and development budget for this project is approximately 600,000 THB for 2023 testing.

Optimization of Bottle Rinser Operation

Osotspa invested over 800,000 THB to taking a holistic view of beverage thermal processing, we studied the optimization of bottle rinser operations. Time and temperature were optimized in the pilot plant to ensure rinser functioned within specifications, while water and energy usage were reduced through modified operating conditions. Optimal rinser conditions delivered high double-digit percentage reductions in both water and energy. This adjustment helps to reduce energy consumption by over 3,064 GJ per year, decrease greenhouse gas emissions by over 257 tons CO2e per year, and achieve savings exceeding 4 million baht per year.

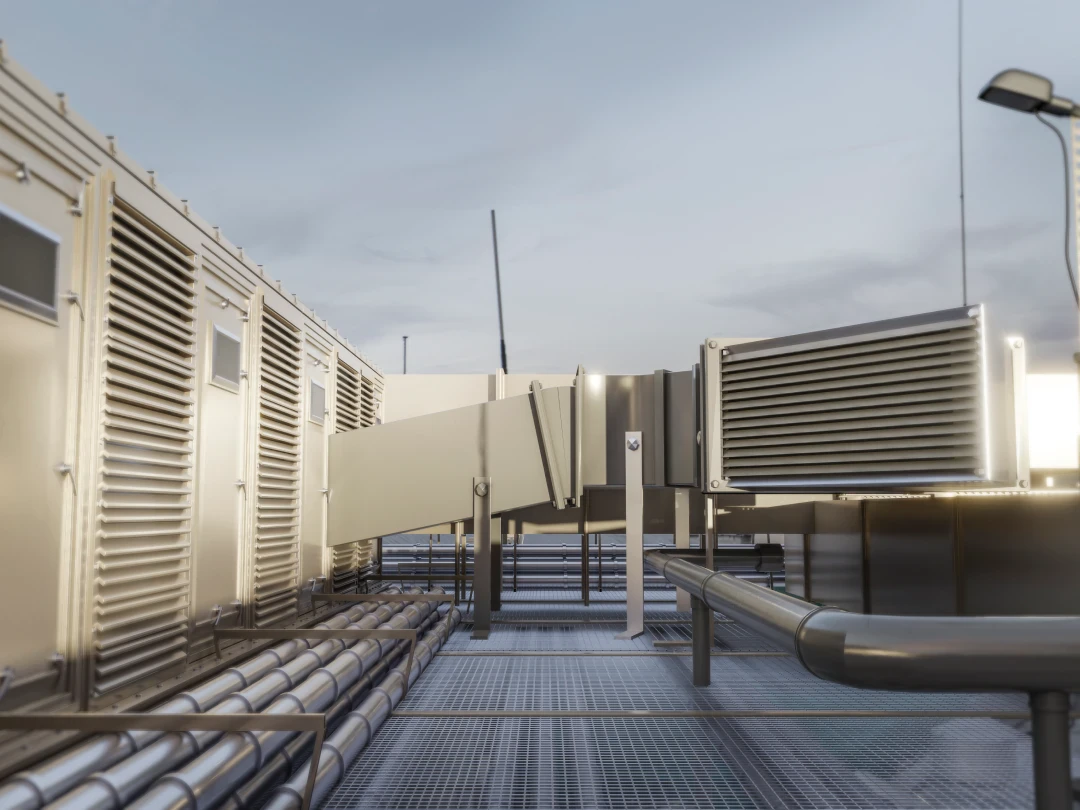

Biomass Steam Boiler Installing

Osotspa invested over 55 million THB to install a horizontal biomass steam boiler with a single drum and a traveling chain grate, using palm kernel shells as fuel. It has production capacity of 15 tons per hour and an efficiency of over 90%, to promote use of clean energy in line with sustainable development goals.

Osotspa Sustainability Workshops

Osotspa provided sustainability training to employees enhance understanding and brainstorm ideas on sustainability, such as reducing greenhouse gas emissions, energy efficiency, water efficiency management and waste management, for operational staff and other relevant departments.

Inverter Installation for Water Pump Cooling System

Adjusts the operating cycles of electric motors to optimize energy consumption and reduce greenhouse gas emissions, while continuously monitoring energy usage data.

Inverter Installation for Air Combustion System

Reduces the operating cycles of electric motors to match usage requirements, while also monitoring energy usage data, to help decrease electricity consumption and reduce greenhouse gas emissions.

Hybrid Generator Installation

Compensates for electricity flow during certain periods, enhances power distribution efficiency, reduces harmonic signals, and decreases primary energy consumption, leading to reduced greenhouse gas emissions.

Biomass

The Biomass Boiler System Project at the Ayutthaya Beverage Plant (BEV AY) involves the installation of a biomass-fueled steam boiler system, utilizing renewable natural energy sources such as palm kernel shells to replace natural gas (NG) for combustion, resulting in a production cost reduction of over 10.5 million baht.

Renewable Energy Production

GHG Reduction

Solar Rooftops

Expansion of solar panel installation for electricity generation within the factory to reduce fossil fuel energy consumption, with a total production capacity of 39,320 gigajoules or 10,922,222.22 kilowatt-hours.

Renewable Energy Production

GHG Reduction

Minimizing GHG Emissions

In line with the UNGC Communication on Progress (COP) & Thailand’s Climate Change Policy, Osotspa has launched initiatives aimed at mitigating environmental impacts through diverse methods, including the adoption of energy from alternative sources. This strategic approach effectively reduces greenhouse gas emissions, aligning with the Company’s objectives.

Osotspa consistently monitors both direct and indirect greenhouse gas emissions (Scope 1 + Scope 2 Market Based), in compliance with the standards set by the Thailand Greenhouse Gas Management Organization (TGO). We also follow the guidelines established by the Carbon Footprint Organization for evaluating and reporting organizational emissions data.